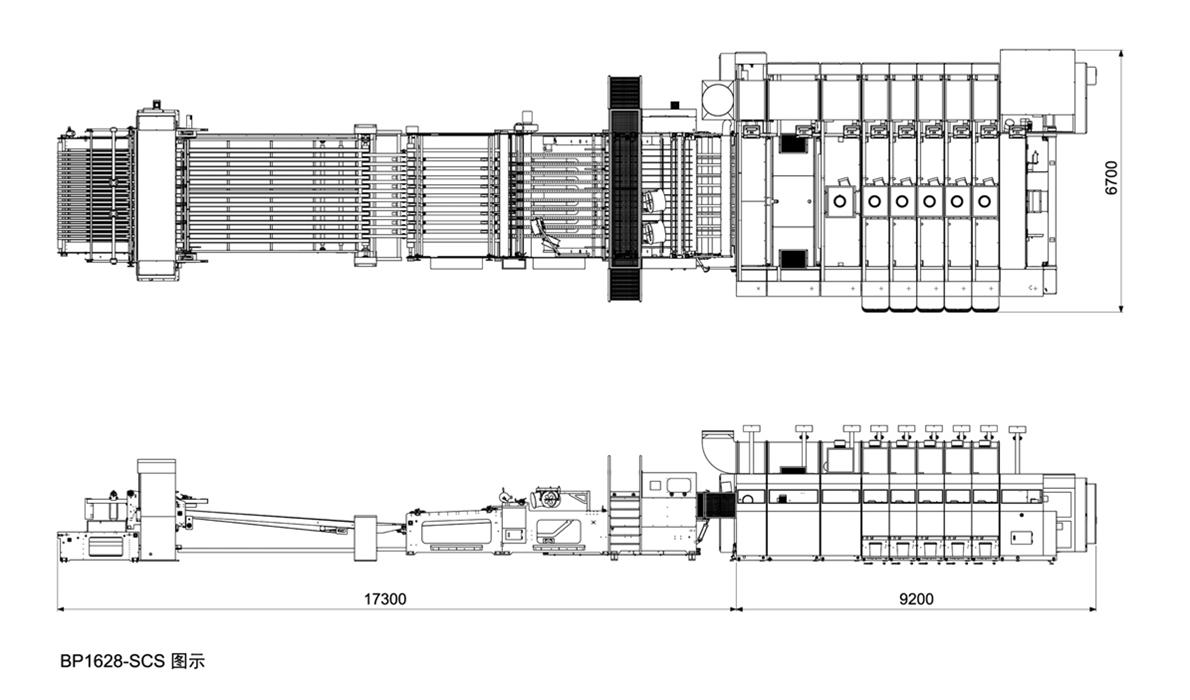

Products

| Series | 1224 | 1628 |

| Max Machine speed

(R/min) |

250 | 180 |

| Max Feeding size

(L × W) |

1200×2400 | 1600×2800 |

| Max Printing area

(L ×W) |

1150×2350 | 1550×1750 |

| Min. Feeding size

(L× W) |

350×690 | 450×690 |

| Standard printing plate thickness | 7.2 | |

Specification: mm

Remark: The output speed depends on how many cavities in one mould.